COLUMN INTERNALS

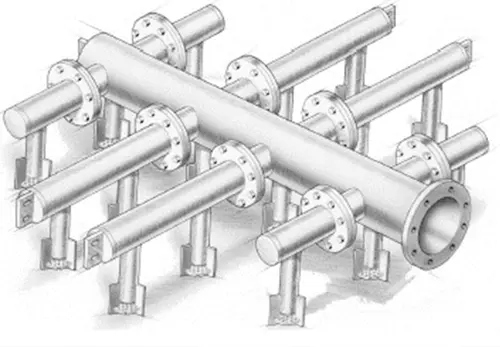

Liquid Distributor

Liquid distributors are used in packed towers above each bed of packing.

The liquid distributor is located above the bed, usually 6 to 8 in (150-200mm) above the packing.

This provides sufficient space for the gas to disengage from the bed before it passes through the distributor.

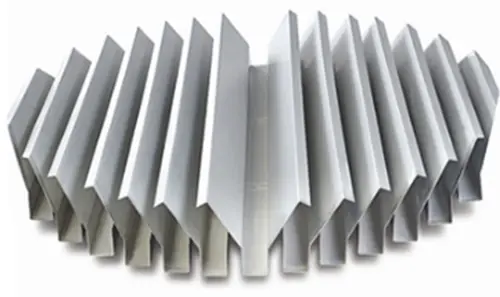

Bed Limiter

Random Packing

For metal and plastic random packings, bed limiters are recommended when there is the potential for sufficient vapor load to fluidize the top of the bed. Generally, this occurs during upset conditions, which are difficult to predict.

Structured Packing

Bed limiters are recommended for use whith structured packing when there is the potential for packing displacement during upset conditions.

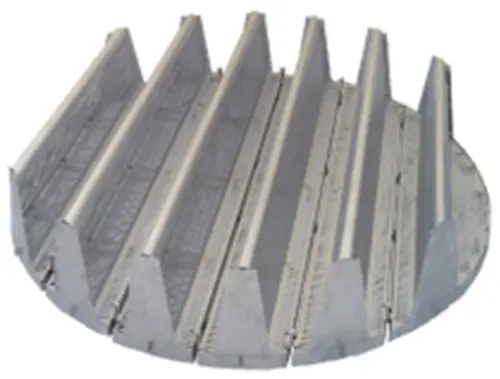

Support Grid

Design of the support grid allows free and uniform passage of gas and liquid so that capacity of the packing is not limited.

Support Plate

Support plates for random and structured tower packings.

Regardless of the packing, each plate incorporates several critical design factors.

First, the plate must physically support the packing under operating conditions.

Second, it must have a high percentage of free area to allow unrestricted flow of downcoming liquid and upward flow of gas. Third, it must be easy to install.

Feed Device

Obtaining desirable tower performance requires the proper handling of liquid and vapor entering the column.

The types of feeds, or inlets, into a column can generally be classified into four major categories:

- Liquid only (contains less than 1% volume vapor)

- -Liquid and vapor above a packed bed (flashing or suppressed flash)

- Vapor only below a packed bed

- Reboiler returns

Liquid/Liquid Extraction

Packing is used in counter-current liquid/liquid contactors with special internals to disperse one of the phase.

Selection and arrangement of the internals depends on which phase (light or heavy) is continuous and which is dispersed.

In all cases, feed pipes directing the feed, light and heavy, are recommended to control velocity.

It is extremely important to properly feed the dispersed phase to the disperser plate.

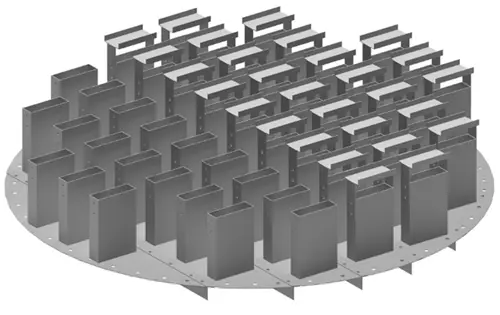

Liquid Collector

Liquid collection from between packed beds is frequently required.

Liquid collectors are used in three main cirnumstances:

- Total draw-off of liquid to product or reboiler or pump-arround/pump-down

- Partial drqw-off of liquid with overflow continuing down the tower

- Collection of liquid for mixing