MIST ELIMINATOR

JET-Mister™

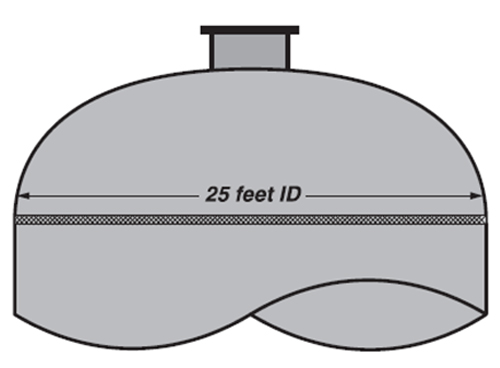

When vessel size is not set by the mist eliminator design, the practical starting point is often the knitted wire mesh pad mist eliminator.

JET-Mister™ provide high collection efficiency and low pressure drop.

Based on years of in-plant performance, JEONJIN engineers can select from a wide variety of mesh styles to meet customer efficiency requirements.

Available in virtually any size or shape in a wide range of metals and plastics, JET-Mister™ is easy to install. Emergency delivery is available.

Features:

- Easy to install in all process equipment

- Most cost-effective solution when equipment sizes are set by other requirements

- High efficiency with low pressure drop

- Emergency delivery available

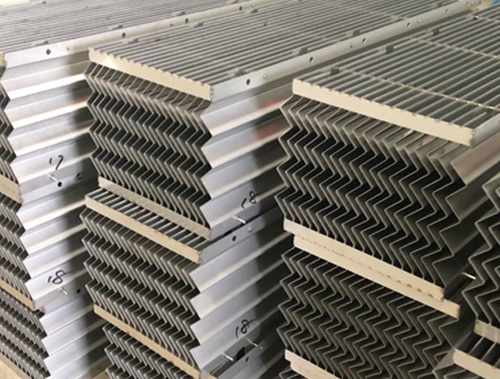

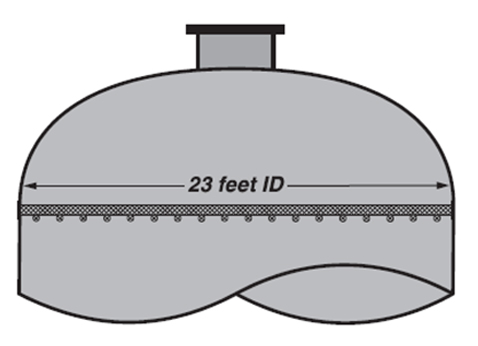

Vane-Pak™

As the liquid mist generated by the process in the tower passes between the zigzag type Baffles, the gas contained in the liquid mist passes through the Baffle, and the liquid mist of a certain size or larger can't passes through the Baffle, forming a droplet form, and then falling down the middle force.

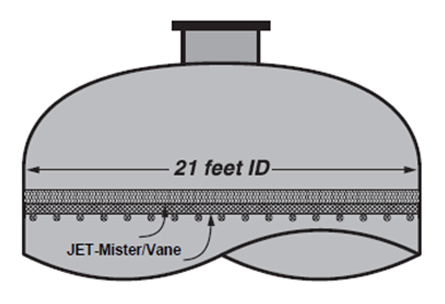

JET-Mister/Vane PLUS™

JEONJIN proprietary JET-Mister/Vane PLUS™ Mist Eliminator simply out-performs conventional pads. Its draining rolls accelerate liquid rem-oval yielding.

When used in conjunction with our Vane-Pak™, JET-Mister/Vane PLUS™ can increase capacity by over 200% as it separates droplets down & up to 3 ~ 50 microns. To prevent liquid re-entrainment, the serpentine path offered by the vane is augmented with obstructions to allow for the pooling of liquid with protection from the passing vapor stream.

The Comparison of Conventional Pad, JET-Mister™ and JET-Mister/Vane Plus™

Option A: Conventional horizontal pad

Option B: JET - Mister pad

Option C: JET - Mister/Vane Unit