PACKING

JMTP

JMTP™ is equivalent to IMTP.

This generation of random packing media designed to give enhanced capacity and increased efficiency over the older style Pall Ring packing.

This type of packing combines the high void fraction and the well-distributed surface area of the Pall Ring with the low aerodynamic drag of the saddle shape.

This kind of random packing is used widely in separation columns.

By comparison to the Pall Ring, JMTP™ provides a more open shape and improved liquid spread, also produce adequate mechanical strength resistance.

Features:

- 30% lower pressure drop rather than Pall Rings

- More efficiency and capacity rather than other random packings

- Minimum liquid hold up

- Well surface utilization in transfer phenomena

- Shorter packed bed height.

- Outstanding mechanical strength

Pall Ring

(Metal/Plastic)

The second generation of random packings includes the Pall Ring which is one of the most common type of packings,

it is already an industry standard design media developed from the Raschig Ring and is used widely in all variety of applications and modern distillation practice.

Features:

- Most experienced random packing in industries and research institutes

- Improved strength by proper material thickness

- Lower pressure drop rather than Raschig Rings

Raschig Ring

(Metal/Carbon/Ceramic/Plastic)

Raschig rings are pieces of tube, approximately equal in length and diameter, used in large numbers as a packed bed within columns for distillations and other chemical engineering processes.

They are usually

ceramic or metal and provide a large surface area within the volume of

the column for interaction between liquid and gas vapours. Raschig rings

are named after their inventor, German chemist Friedrich Raschig.

Cascade Mini Ring

(Metal/Plastic)

The low aspect ratio of Cascade Mini Ring random packing results in preferential orientation when loaded into the tower, which can increase capacity and reduce pressure drop.

JEONJIN offers multiple sizes of this packing to optimize the efficiency and capacity for your specific applications.

The geometry of the Cascade Mini Ring random packing provides higher efficiency by more efficient use of the packing surface.

The open structure inhibits fouling by allowing solids to be more easily flushed through the bed by the liquid.

Size:

- Metal: 1, 1.5, 2, 2.5, 3, 4, 5

- Plastic: 1A, 2A, 2, 3A

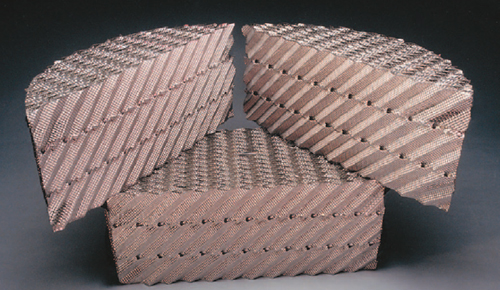

(JET-PAK™) Equivalent to MELLAPAK series

Size: 125Y, 250Y, 350Y, 500Y

(JET-JSP™) Equivalent to INTALOX series

Size:

1Y, 2Y, 3Y, 4Y, 5Y

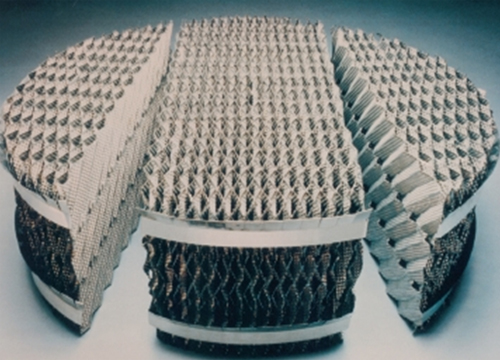

Structured Packing

Structured packing is formed from corrugated sheets of perforated embossed metal, plastic (including PTFE) or wire gauze.

The result is a very open honeycomb structure with inclined flow channels giving a relatively high surface area but with very low resistance to gas flow.

The surface enhancements have been chosen to maximize liquid spreading.

These characteristics tend to show significant performance benefits in low pressure and low irrigation rate applications.

Features:

- High void volume in the packing bed

- High mass transfer surface area

- Very low pressure drop, highly recommended for vacuum distillation system

- Higher vapor load capacity compared to random packing and trays

- Pressure drop per theoretical stage 0.5-1.5 mbar/m (For Standard System)

(JET-JSP Plus™) Equivalent to MELLAPAK PLUS series

(JET-JSP Plus™) Equivalent to MELLAPAK PLUS series