TRAY

Bubble Cap Tray

A bubble cap tray has riser or chimney fitted over each hole, and a cap that covers the riser.

The cap is mounted so that there is a space between riser and cap to allow the passage of vapour.

Vapour rises through the chimney and is directed downward by the cap, finally discharging through slots in the cap, and finally bubbling through the liquid on the tray.

Sieve/Dualflow Tray

Sieve trays are simply metal plates with holes in them.

Vapour passes straight upward through the liquid on the plate.

The arrangement, number and size of the holes are design parameters.

Consists of tray panels area uniformly punched with holes hence is the cheapest mass transfer device because of simplicity and cost-effectiveness.

Dualflow Tray is Sieve Tray without downcomers.

Valve Tray

Valve Trays are composed of punched tray decks fitted with movable valves to vary the tray open area with changing vapor load.

In cases where high turndown ratios are considered, valve trays are an option.

Valve discs/caps are available in both round and rectangular shapes.

The capability of valves makes these valves can control vapor flow so as a result, they provide better sustained efficiency over a wider operating range than sieve trays.

JET-HPF™ Valve Tray

JET-HPF Valve Tray is a JEONJIN's High-Performance Fixed Valve Tray.

The structure and operation are stable, and maintenance is needed less.

It has excellent fouling resistance and better surge protection.

Prices are also economical and easy to install.

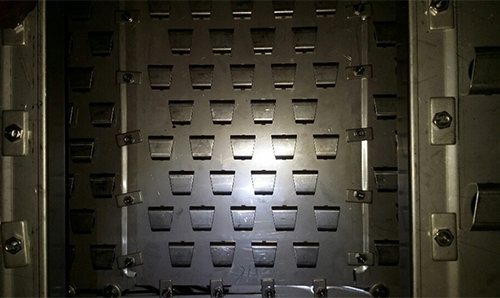

JET-Frac™ High Capacity Tray

JET-Frac™ High-capacity Tray are proven to provide substantially greater capacity than conventional trays.

The capacity is substantially greater than the traditional tray type and the efficiency is equal or improved.

Available as a metal material, it is mechanically strong, economical, and easy to install.

Features:

- Enhanced downcomer design

- Maximizes active bubbling area

- Forward-lateral vapor release inhibits fouling

- High valve lift minimizes pressure drop

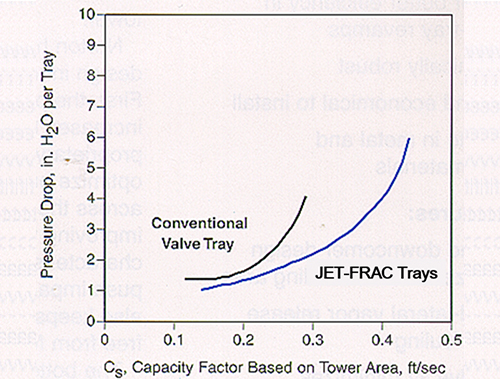

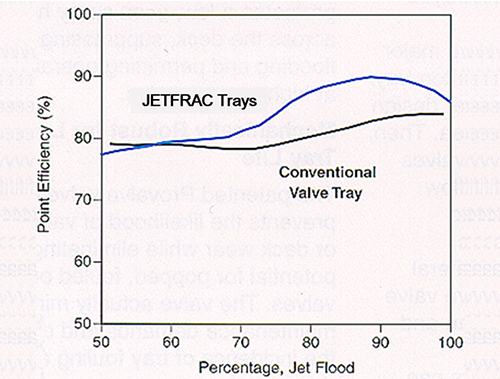

The Comparison of JET-Frac™ Tray and Conventional Valve Tray

Efficiency

Pressure Drop