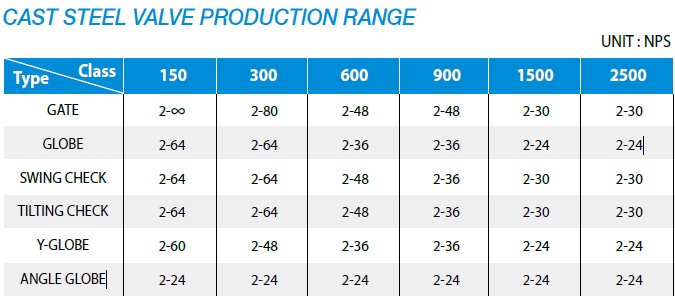

CAST STEEL VALVE

SERVICE FEATURES

• Several trim combinations available for various services.

• Straight-through port design offering a good flow with minimum frictional loss and turbulence.

• Cast steel Valve suitable for works demanding strength, shock resistance, elongation and heat resistance.

• Bottom seating of seat rings ground accurately for maximum strength and tightness(globe).

• Bypass mounting to equalize pressures.

• Normal yoke bushing furnished with ductility resistant to high melting point of above 2200°F.

• Level and weight available to accelerate/decelerate disc closing (swing check).

• Designed for maximum flow with minimum pressure drop if possible.

• Precision-ground seating surfaces and revolving disc providing a long life.

In the refineries, power plants, utilities and petrochemical/chemical process industries, PK cast steel valve

have been regarded as of great importance about their excellent performance and reliability.

By discriminatory blending of carefully selected materials combined with sound design and precision

machining/assembly under strict quality controls, PK steel valve have gained general and wide acceptance.

The products are manufactured in accordance with ASTM, ANSI, or other international standards.

PRODUCTION MATERIALS

• Carbon Steel : ASTM A216-WCB or Equivalent

• Alloy Steel : ASTM A217-WC6, WC9, C5, C12, C12A or Equivalent

• Stainless Steel : ASTM A351-CF8, CF8M, CF3, CF3M, CN7M, or Equivalent

• Duplex Stainless Steel : ASTM A995-1A, 2A, 4A, 5A or Equivalent

• Special Alloy Steel : Inconel 625, Incoloy 825, Hastelloy C, Monel, AL-BRONZE

• ASME SA designation material(e.g ASME SA217-WC6)

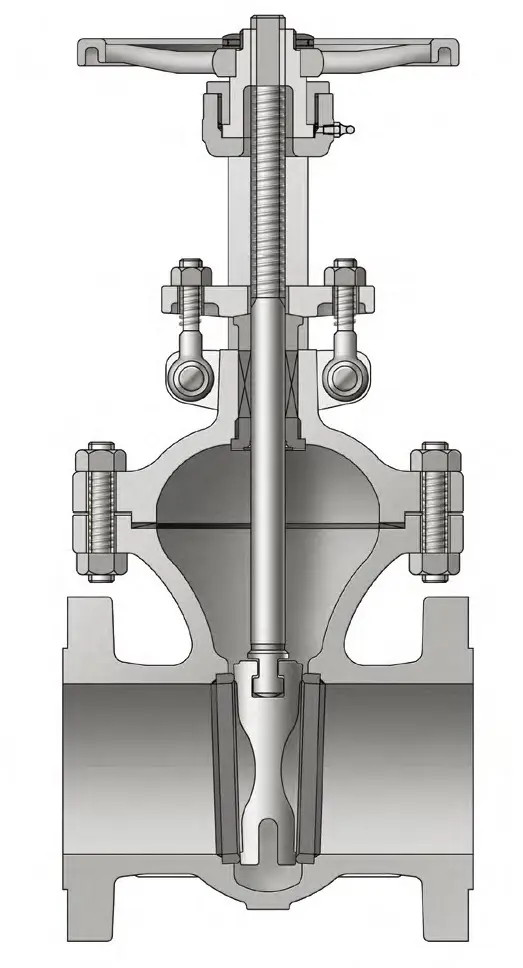

Gate Valve

Gate valve is characterized by a sliding wedge which is moved by actuator perpendicular to the flow direction. There are a variety of valve sizes and types.

The valve is used primarily as a stop valve to open or close fully. Normally it works for slurries, viscous fluid, etc.,but not for throttling.

The gate valve usually has a minimum pressure drop in full open and a tight seal in full close, and therefore there is little possibility that contaminants may enter the valve.

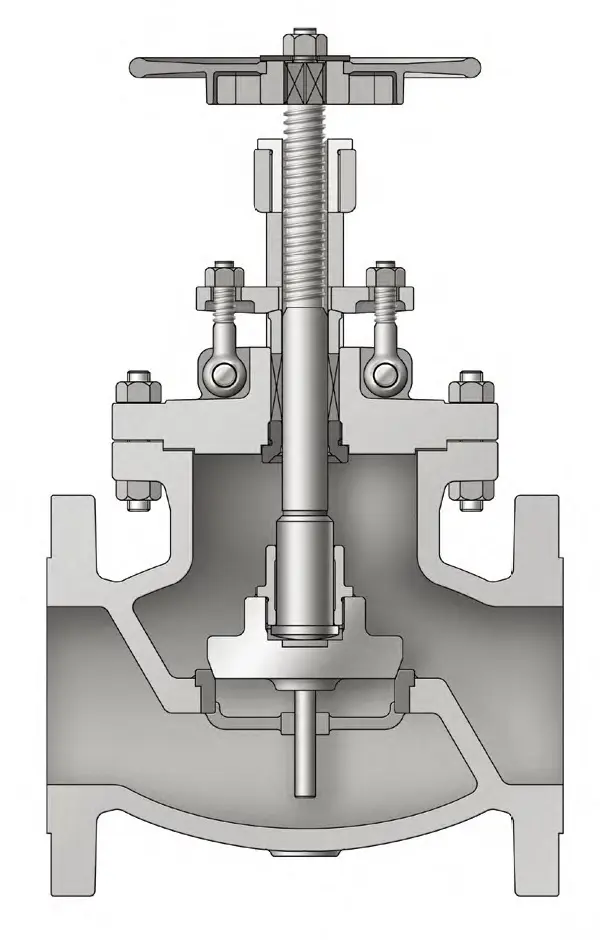

Globe Valve

The globe valve is used where throttling alone or both throttling and shutoff is needed.

It may also be used for on-off service, but because of high pressure drop, such application is limited to the cases that the valve is normally closed and the pressure drop is of no importance in valve open condition.

PK cast steel globe valve is regularly made in outside screw and yoke design with full-way type disc.

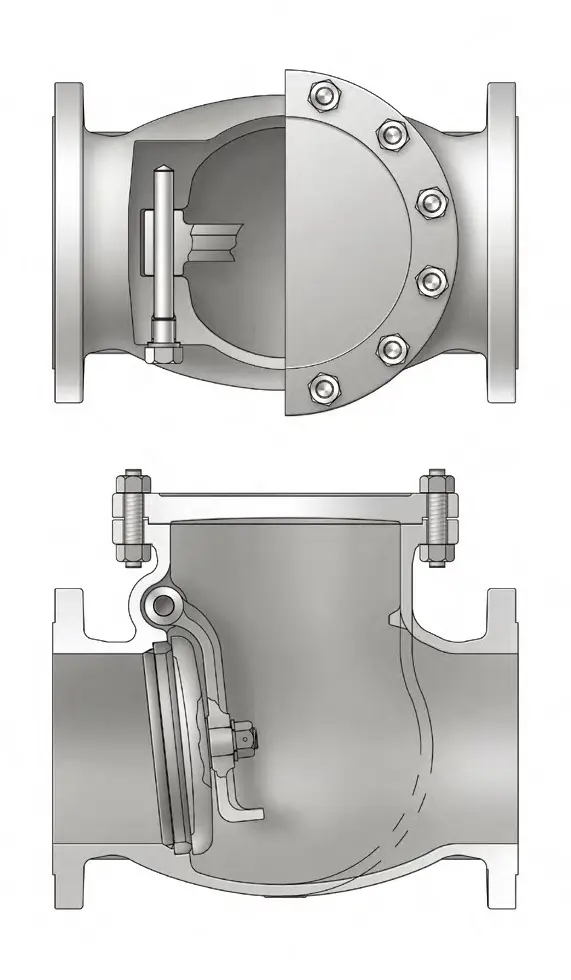

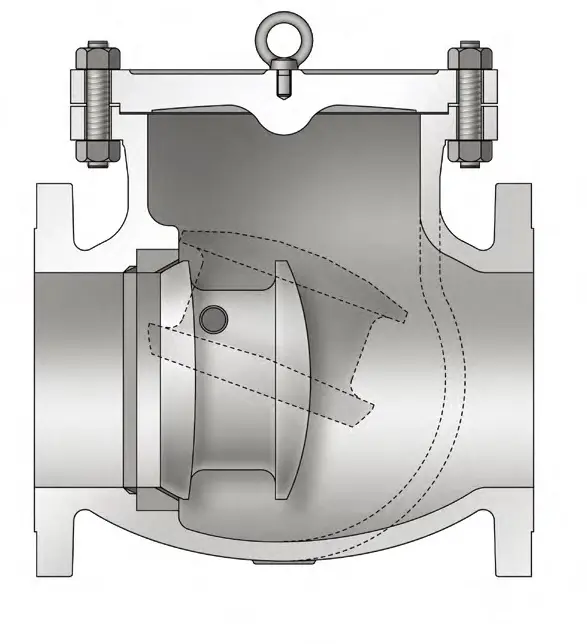

Swing Check Valve

The swing check valve is designed so that it is opened automatically at the forward flow and closed at the reverse flow in horizontal or vertical (upward flow only through valve) piping runs.

It has an advantage of low pressure drop and therefore is best suitable for velocity application.

Tilting Disc Check Valve

Today, higher velocity and pressure of piping often requires a sophisticated check valve rather than conventional swing type valve.

PK tilting disc check valve is designed to handle such higher velocities, prevent damages due to turbulence and avoid “water hammer”phenomenon in piping systems, and it is closed quickly and quietly.

The valve is closed quickly because its pivot(hinge pins) is shut by a very small arc.Moreover, line fluid flows both over and under the disc, so that valve closing is cushioned by the line fluid itself.

By virtue of quick and quiet closing ability, up to now PK tilting disc check valve has earned good reputation as a “non-slam”check valve.

Dual Plate Check Valve

Dual plate check valve are supplied retainerless as standard.

Our patented design does not have any threaded plugs in the pressure boundary and totally eliminates the potential leakpath to atmosphere.

This design meet

fugitive emission control.